parts WASHING

Whether your application requires a standard top or front load washer, an automated belt system or a fully customized vapor degreaser, we have the cleaning equipment you need.

Aqueous cleaning systems

Vapor degreasing equipment

Ultrasonic Cleaning

Free Testing

turntable washers

Top and front load turntable parts washers are ideal for batches of parts or larger parts that require special handling. An infinite array of sizes and fixtures are available.

tumbling washers

Tumbling washers are available in a number of configurations and are primarily used for small parts that require a superior level of cleaning. These washers offer both spray and immersion.

inline washers

With an inline washer, parts are loaded on a belt and moved through a series of stations to fit your requirements. Wash, rinse, pretreat, and dry are some of the available stations.

vapor degreasers

With the ability to clean parts with blind holes and complicated geometries, vapor degreasing can solve some of the most complicated cleaning needs.

Turntable Washers

Standard turntable washers are cost effective solutions to thousands of cleaning applications. Email us today for a complimentary consultation. sales@industrimax.com

Front load and top load turntable washers are used in thousands of applications. Whether you are cleaning a cylinder head, landing gear components, or any other large (or small) part that needs cleaning, there is a turntable washer to fit your application. Options such as heated air drying, heated water, additional nozzles, advanced filtration, and oil separation are all commonplace. From a small 24″ turntable to a 10′ table, we can fit your part into one of our systems.

Email us today to set up a free test for your application. sales@industrimax.com

Top load systems for your parts with a minimal height requirement.

Front load systems for your taller parts.

.

Our Mission

INDUSTRIMAX IS DEDICATED TO PROVIDING OUR CUSTOMERS WITH SOLUTIONS TO ALL OF THEIR SURFACE FINISHING AND PREPARATION NEEDS. WE ARE COMMITTED TO HELPING OUR CUSTOMERS IMPROVE THEIR FINISHING PROCESSES AND LOWER THEIR TOTAL FINISHING EXPENSE.

Tumbling Washers

For your more delicate parts or those requiring a higher degree of cleanliness. Email us today for a complimentary consultation. sales@industrimax.com

Tumbling washers are used for smaller parts that have a higher level of cleaning required. medical devices and aerospace fasteners are among some of the more common parts run in these systems.

Email us today to set up a complimentary test for your parts. sales@industrimax.com

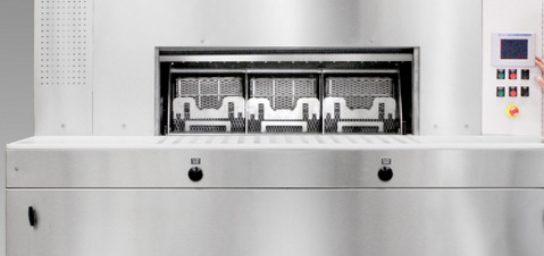

Inline Washers

Inline washers can be used in thousands of applications. Email us today for a complimentary consultation. sales@industrimax.com

Inline washers are designed for multi-stage cleaning applictaions for parts of varying sizes and materials. These systems have the option of treating your part with multiple chemistries, multiple rinsing stations and drying stations. Water, and cleaning solutions can be filtered and recycled for optimum efficiency. Inline systems are designed specifically for you application in order to provide the ideal solution to your cleaning needs.

Email us today for a complimentary consultation on your cleaning requirements. sales@industrimax.com

Vapor Degreasers

Vapor degreasers are a great solution to cleaning and degreasing parts with complicated geometry, delicate surfaces and blind holes. Email us today for a complimentary consultation. sales@industrimax.com

From a small unit for small batches or an individual part to a fully automated system capable of processing thousands of parts in one batch, we have a solution for your parts degreasing and cleaning.

Email us today for to schedule your complimentary test. sales@industrimax.com

batch systems

Batch systems are ideal for applications involving small batches or individual parts. These systems are available in a number of different configurations with hundreds of different options.

automated systems

Automated systems are designed based on your parts and are intended for large production runs with critical cleanliness requirements. Customized material handling and other options are commonplace on these systems.

airless systems

Airless systems are designed for cleaning parts with complicated, traditionally difficult geometry and blind holes. These systems provide the most comprehensive cleaning and degreasing. Material handling and other options are available on these systems.